The production of packaging using the laminating method is the process of pressing one material (liner) onto a denser base. In this case, the liner is coated paper or binding (flat printing) cardboard for small box sizes, with an image applied using offset printing. Corrugated cardboard or micro-corrugated cardboard (two- or three-layer) can serve as the base. When producing packaging from laminated micro-corrugated cardboard, the surface is the smoothest and most attractive. The top layer is laminated or coated with offset, water-dispersion, or UV varnish.

Laminating cardboard is currently the only way to apply a high-quality full-color image to a dense base. Moreover, the price-quality ratio of laminated cardboard packaging is always quite acceptable for serious manufacturers.

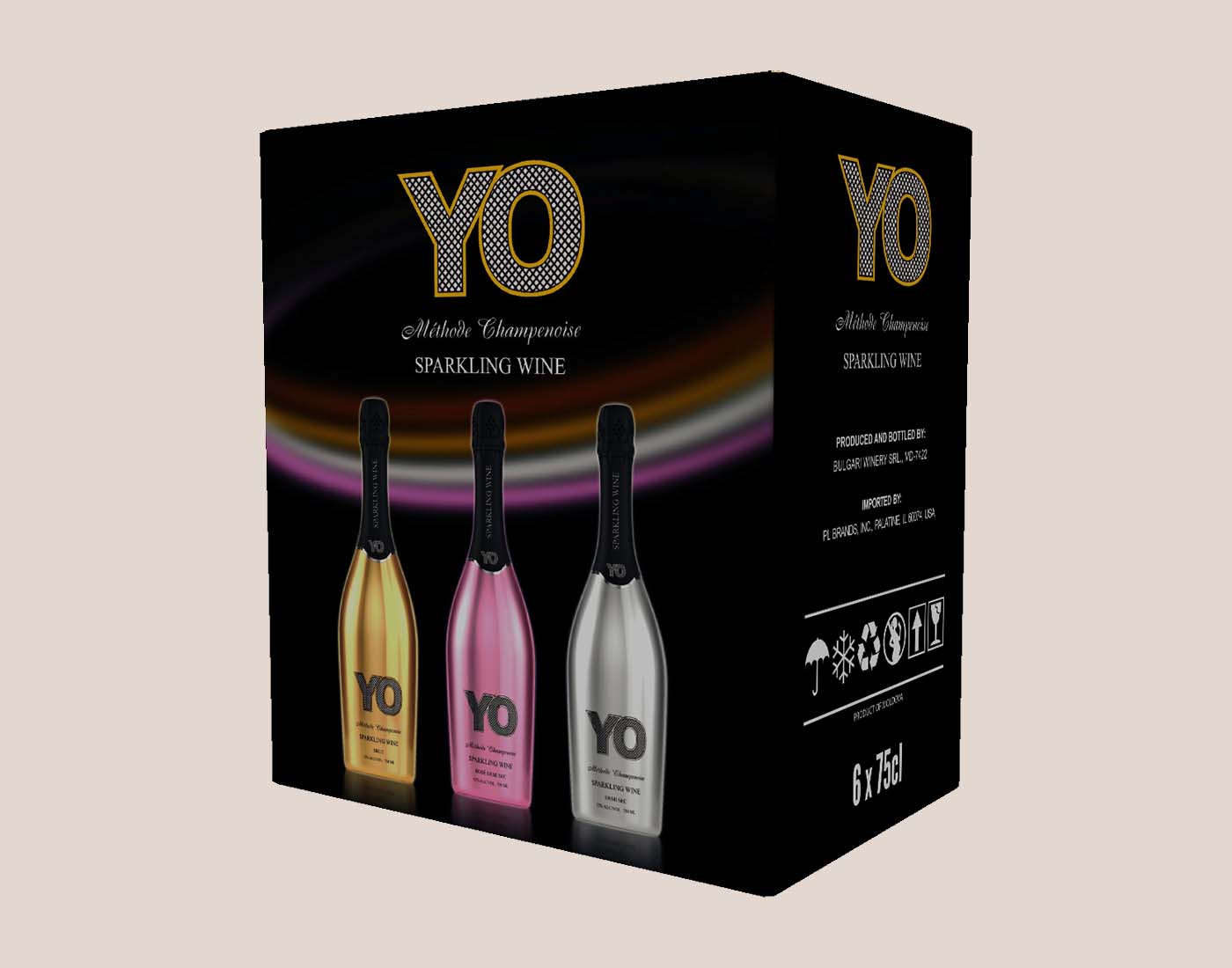

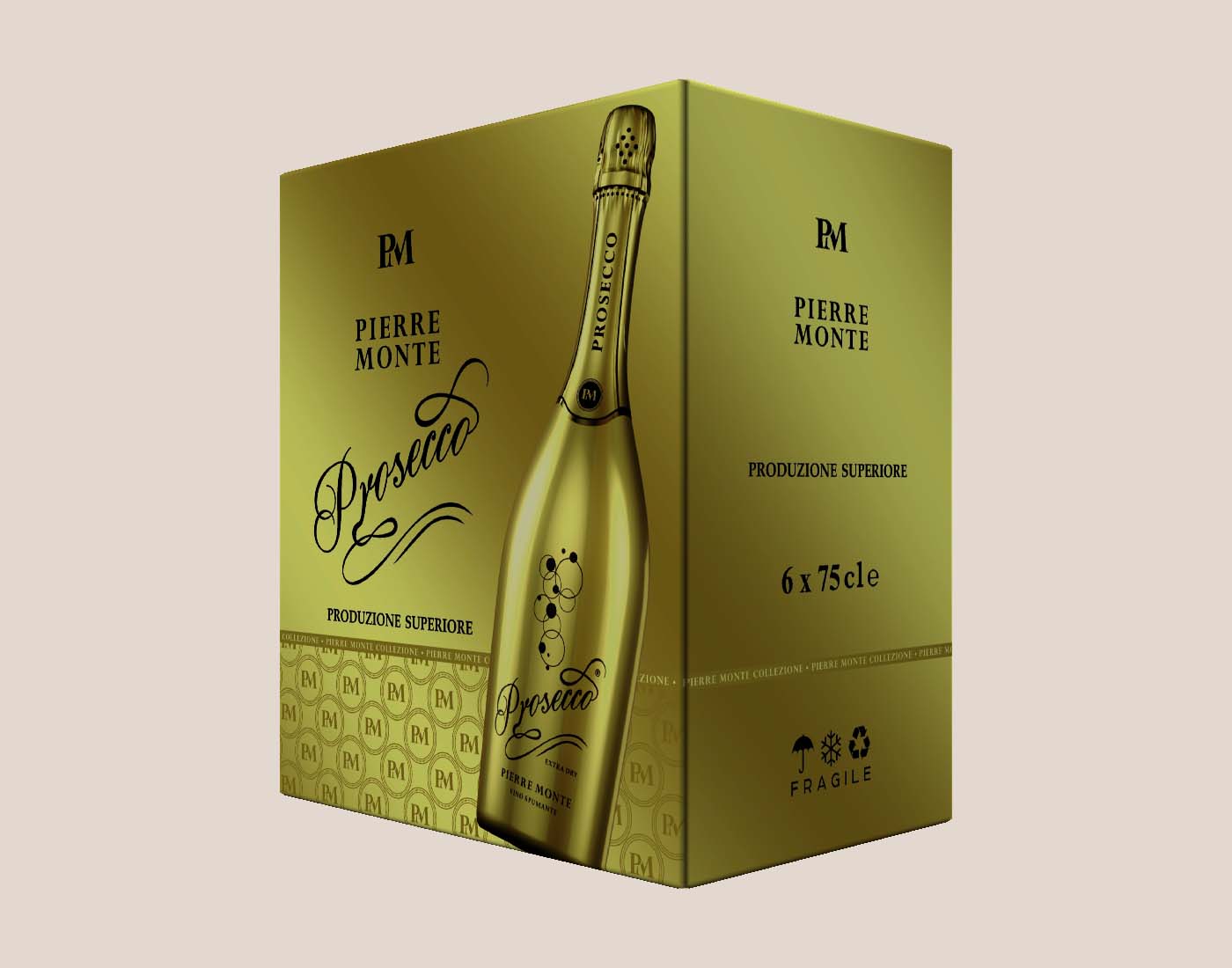

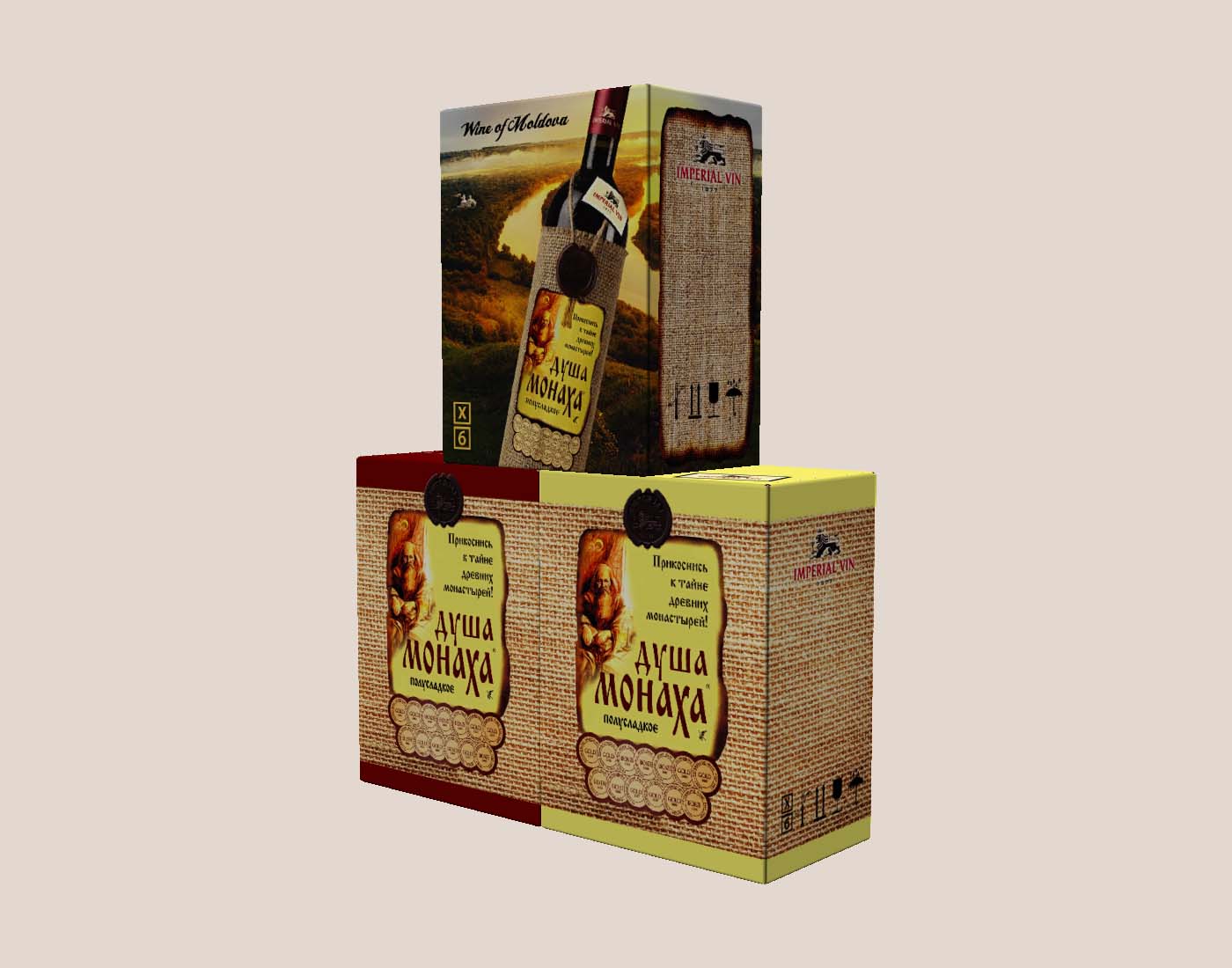

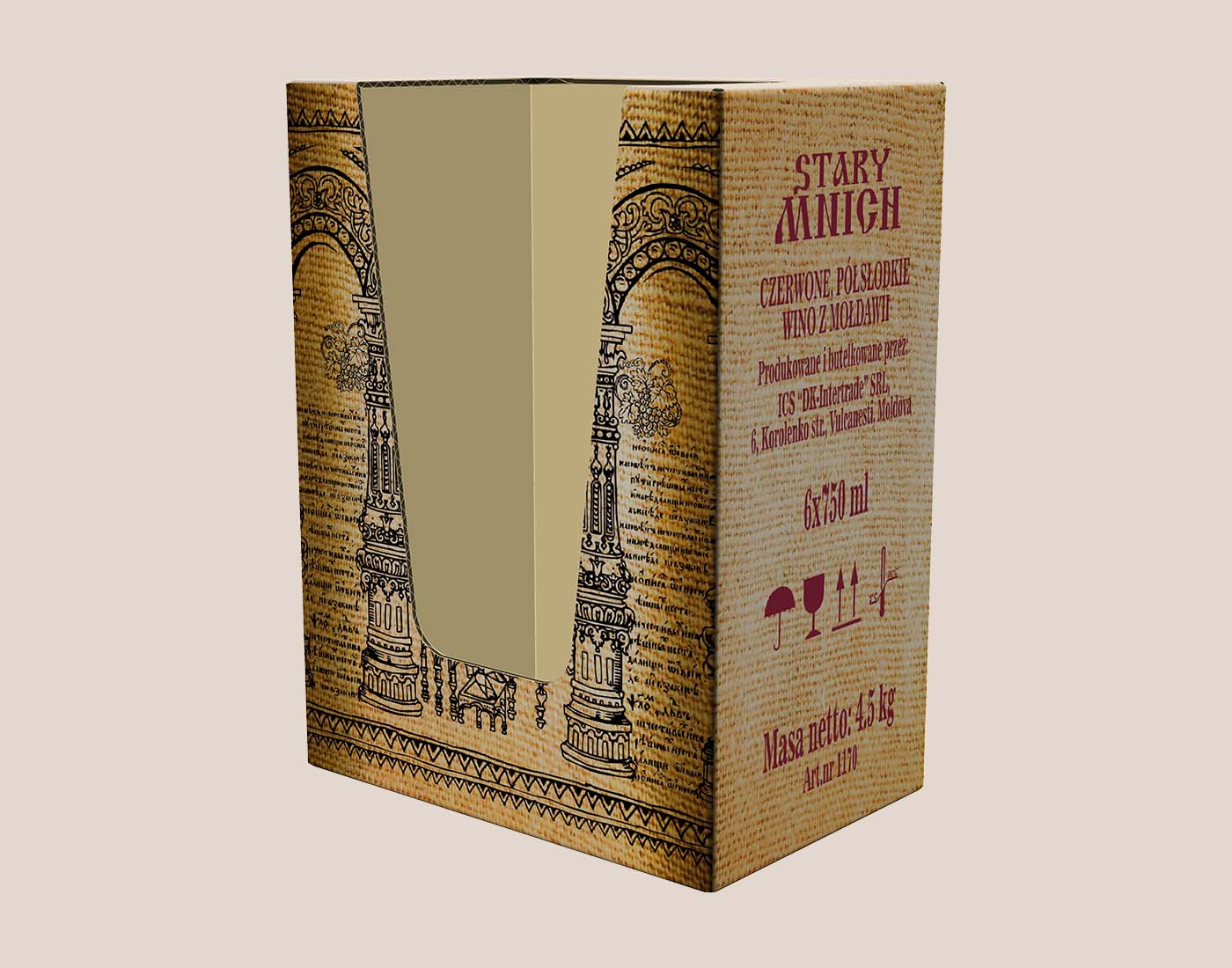

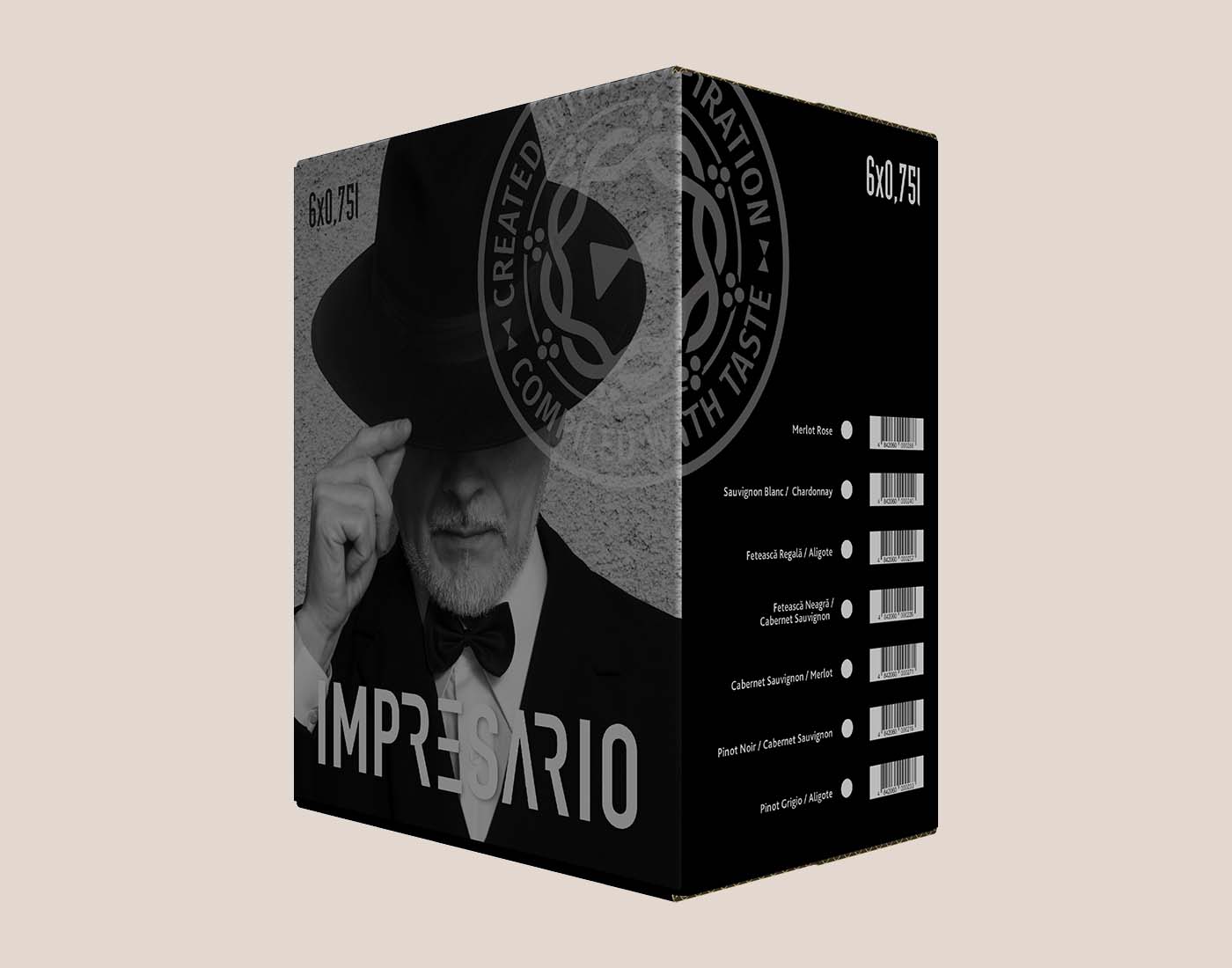

Laminated cardboard packaging is used for packaging components and consumables, electrical lighting and household appliances, sanitary ware, office equipment, tableware, textile products, toys, as well as alcoholic beverages, etc.

Laminated cardboard packaging has a more attractive appearance than flexographic printing packaging. Undoubtedly, this has a positive effect on the sales volumes of the products packaged in such boxes. Thus, companies and enterprises that have switched to this type of laminated cardboard packaging have found that, in addition to the quality of their products, their design often plays a very important role. And the ability to present goods beautifully is valued, first and foremost, by product buyers.

Glossy or matte selective UV varnish, foil stamping, embossing, and lamination are available.

The production time for laminated packaging is 10 to 15 days.